The Invention of PEEK Plastic Revolutionized the Component Manufacturing Industry

PEEK was invented in the UK in 1978 and received a US patent in 1982. The processing conditions implemented to mold the material influence its crystallinity, or structure, and this results in the superb mechanical and chemical resistance properties of PEEK. PEEK is also highly resistant to degradation under high temperatures and resilient in organic and aqueous conditions. These properties make PEEK ideal for a wide array of components in diverse industries. Some of the major fields where this dynamic plastic material have been most effective are aerospace, the medical space, food & beverage and also the manufacture of PEEK plastic bearings.

PEEK has become an Invaluable Material in Aerospace Components

PEEK is optimal in aerospace due to its light-weight, chemical inertness and inexpensive characteristics. Light-weight materials reduce the overall load of a vessel and, thus, reduce fuel costs and helps preserve the environment. Because PEEK is a chemically inert, the material is stable in extreme conditions and can withstand exposure to atmospheric particles. The fact that PEEK is inexpensive to manufacture cuts back on the comprehensive cost of components.

In the medical field, hygiene, durability and biocompatibility are all important factors when considering material for medical devices and components. PEEK offers flexible and durable properties and it is also has no adverse effects on the skin or internal organs, which makes it an ideal material for implants. Its resistance to extreme temperatures and low moisture absorption properties also make it a preferred choice for pumping mechanisms.

The high-temperature resistance of PEEK makes it a favorable option in the production of powders and other ingredients in the food & beverage industry. PEEK is an inexpensive alternative to PET and holds up well under the extreme temperatures for the drying of ingredients in food as well as feed for animals.

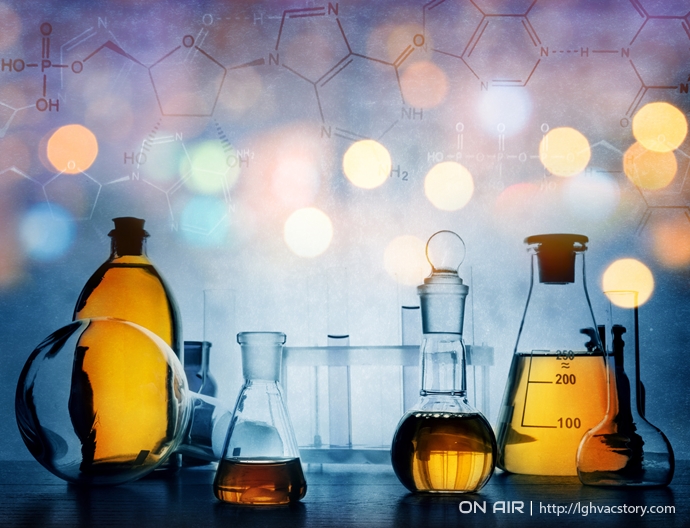

PEEK Plastic Bearings (ⓒflicker by Creative Tools)

One field that has some of the most diverse applications of PEEK is the manufacturing of components and PEEK bearings are one of the most effective components to come from PEEK manufacturing. The function of a ball bearing is to reduce rotational friction between 2 moving mechanical elements. PEEK makes an ideal material for bearings for many reasons. PEEK bearings are self lubricating once they begin to move. Abrasion causes microscopic bits to function as lubrication with inconsequential alteration to the bearings themselves. The durability and high-temperature resistance of PEEK bearings allows them to be thinner and lighter than traditional material bearings. Their light-weight characteristics make them more fuel efficient and they don’t require as many additional chemical additives produce that aluminum or steal require. PEEK is inexpensive and can reduce bearing production costs significantly. PEEK bearings also require little maintenance and can run for long periods of time without freezing during operation. These components are simple and convenient to replace when necessary. The chemical resistance of PEEK bearings makes them resistant to damage incurred by metal bearings. All these attributes make PEEK bearings an exceptional mechanical component for endless number of products and functions

LG is also implementing this revolutionary PEEK bearing technology in their new Multi V 5 air conditioner system. The bearings that drive LG’s own scroll system are the same PEEK bearings that are used in aerospace applications. The next-generation technology allows components to run longer without additional lubrication and makes LG’s groundbreaking Multi V 5 system air conditioning products even more durable and reliable.

INVISIBLE INNOVATIONS

As we can see from these examples, PEEK plastic is effective in a range of industries and PEEK bearings have become a favored option as a mechanical component. PEEK bearings can be found in many different types of products and even in motors that go into the refrigerators and air conditioners in our homes. PEEK bearings will continue to be implemented in more and more products in the future as well. Keep your eyes open for PEEK plastic materials and PEEK bearings in the machines and products around you.

[1] Source: http://info.craftechind.com/blog/bid/377279/Why-PEEK-Material-is-at-the-Top-of-Its-Class

[2] Source: http://drakeplastics.com/peek/